What is 3D Machine Printing and How Does It Work?

3D machine printing is evolving, making manufacturing more convenient and has a lot of potential for the future. This printing production can produce more complex geometries than traditional technologies, making it a popular manufacturing solution in different fields.

What is 3D Machine Printing?

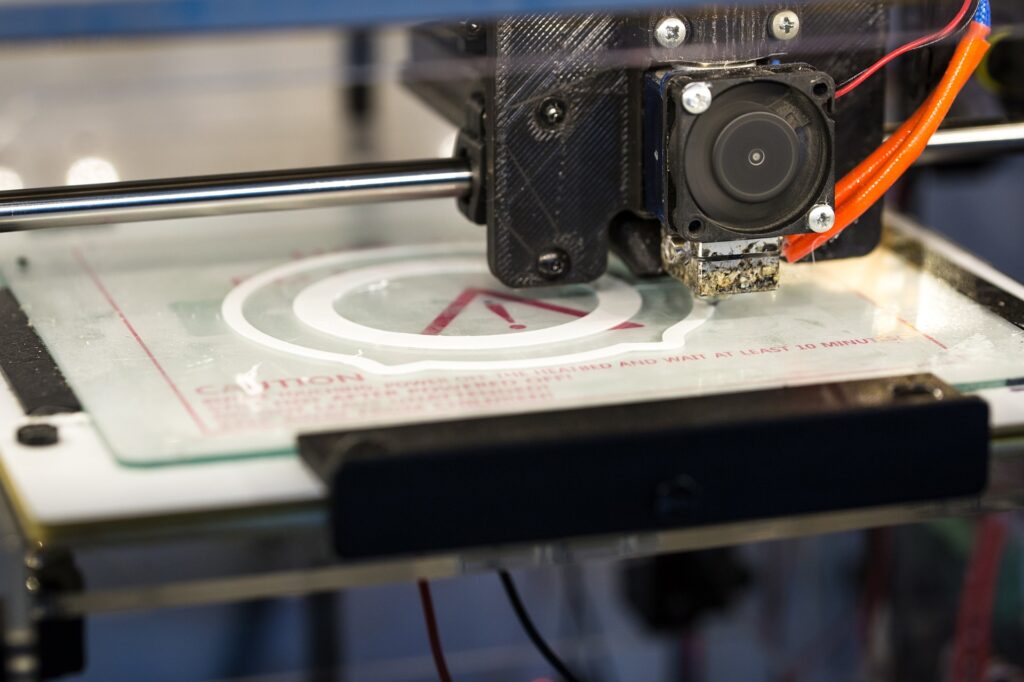

Three-dimensional printing is an additive manufacturing process that simply involves creating physical objects from a virtual design. It involves printing thin layers of the desired design and fusing it to form a three-dimensional object. 3D machine printing is considered an additive manufacturing process because it builds objects from scratch.

How Does 3D Machine Printing Work?

3D machine printing involves a process that turns digital models into solid, 3 dimensional objects. This is usually achieved by laying down many successive, thin layers of material and joining them together to build an object. To create a 3D design, first, a digital design of the object needs to be made to serve as a blueprint for a 3D printer to read. This virtual design is made using computer-aided design (CAD) software. Also, a 3D scanner can be used to create virtual images by taking pictures of the object at different angles.

Slicing

Once you have a virtual design of the object, you can then break down the model through a process called slicing. The process slices the virtual design into many horizontal layers using special software. Once the slicing process is done, the file is uploaded to a 3D printer which reads the file and prints it according to the created layers.

Benefits of 3D Machine Printing

3D has become so popular because it makes manufacturing more accessible and easy. It allows the printing of more complex and intricate designs compared to the traditional manufacturing process.

With 3D machine printing, designers can conveniently turn models into 3D designs (rapid prototyping) and produce on-demand rather than in large quantities. This saves space and reduces wastage.

Also, 3D saves a lot of money as only little raw materials are wasted during the process compared to the subtractive process.

What Kind of Things Can Be Created with 3D Printers?

Additive manufacturing solutions like 3D printing make it easy to turn complex designs into actual products using fewer materials than subtractive manufacturing processes. With 3D printers, engineers, designers, cloth manufacturers, and everyone can create complex designs that traditional manufacturing methods cannot do. This includes objects like jewelry, furniture, pottery, arts, clothing, phone cases, toys, lamps, cars, etc.

In the medical field, surgeons are adopting 3D medical models to run a practice on a patient’s 3D model before operating on the patient. 3D is also used to customize implants.

In addition, some industries like car manufacturers, aircraft manufacturers, hearing aid manufacturers, and prosthetics manufacturers use 3D to create prototypes and mass produce their products. 3D is especially popular in the fashion industry as brands like Nike and Adidas use this manufacturing process to create shoes. Artists also use 3D printing to create sculptures, and architects can fabricate models of their projects.

Getting 3D Printing Services

Owning a 3D printer is possible by buying from manufacturers or sellers. However, you don’t need to own one to benefit from it. There are different 3D printing services available to help customers create their 3D designs. All you need to do is send your 3D files or choose an object, and you will have it designed.